What Is Parametric Design and How It's Used In Architectural Millwork?

Parametric design is transforming how architectural millwork and custom fabrication are created. Instead of relying on fixed dimensions, this method uses digital rules and relationships that let designs automatically adapt when variables change. By linking parameters like width, height, or material thickness, we can quickly adjust components without redrawing every detail. This approach improves accuracy, efficiency, and flexibility.

What is Parametric Design?

Parametric design is a method used in 3D manufacturing. In short, parametric design is about building relationships between dimensions instead of using fixed ones. For a design to be parametric, it must follow a set of rules defined at the start. The types of rules could be anything from dimensions, angles, materials, or the relationship between parts.

Some examples of how we apply parametric design to our architectural millwork projects are: cabinet parts that automatically resize when the overall width or height are changed, joinery or hole spacing that adjusts automatically to thickness changes, and toolpaths or jigs that scale to match material sizes.

What Is Non-Parametric Design?

Non-parametric design is what you may traditionally think about when thinking of designing. A product designer manually creates each element of the design. When making changes, they must re-enter every adjustment to keep the design within the client’s parameters.

Because there are no predefined rules or realtionships between dimensions, non-parametric methods can be slower and more prone to error. Even small adjustements, such as changing a panel width or material thickness, can mean redrawing multiple parts of the project.

Non-parametric methods are still common in custom work or one-off builds where flexibility artistic control matter more than repeatability.

How Does Parametric Design Change How We Manufacture Products?

Parametric design allows us to create complex systems that would be impossible to design by hand. At the same time, we can design multiple parts without manually plotting every measurement.

Using parametric modeling, designers can input the variables while software uses its built-in algorithmic capabilities to ensure all the requirements are achieved before a prototype is even created.

Examples of Parametric Design.

Here are some of the architectural millwork projects we’ve completed using parametric design.

- Architectural panels and siding

Automatically spaces holes, joints, based on panel size, layout grid, or material thickness.

- Structural or decorative components

Timber brackets, trusses, or column wraps that adjust automatically based on beam size or span.

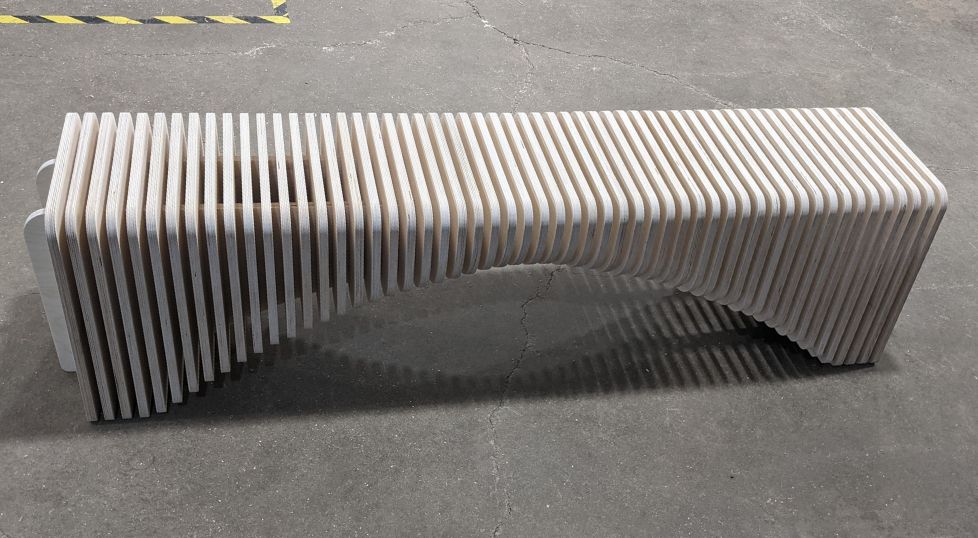

- Outdoor furniture or benches

Seat length, angle, and leg spacing can all be parameter-driven.

- Acoustic panels or perforated screens

Pattern density or hole size can change automatically depending on sound absorption target, panel size, or design intent.

- Custom crates and packaging

Automatically calculates wall sizes, handle cutouts, and fastener locations based on product size and weight.

- Signs and branding elements

Letter spacing, material thickness, and mounting holes adapt to different sign sizes or fonts.

- Molds, jigs, and templates

Makes it easy to create new sizes or profiles for repeat tooling or curved parts without rebuilding the geometry each time.

How Do We Use Parametric Design?

Recently we used a parametric approach on a recent commercial siding project. Our CNC shop built a custom parametric file generator that places all the hole locations based on the overall panel size. This saves us the hours it would take to manually generate individual cut files. With this system the generative design does the majority of the work for us, and every panel will be perfectly accurate.

Does Your Project Require a Parametric Design Process?

Not every project needs a parametric approach, but many benefit from it. Projects with repeating components, complex geometry, or strict tolerances are ideal candidates for parametric modelling. By automating the relationships between parts, we can quickly adapt to design revisions, scale production efficiently, and maintain precision across every element.

For simpler, one-off builds, a non-parametric process may still be the most practical solution. Our team evaluates each project individually to determine which approach delivers the best results. Whether your design calls for custom architectural panels, detailed joinery, or high-volume parts production, we apply the right tools and methods to complete your project efficiently and accurately.

If you’re unsure which process fits your needs, we’ll handle that for you. Our design and manufacturing teams work together to choose the most effective workflow—so you get a seamless, high-quality result without having to think about the technical side.